Our processes

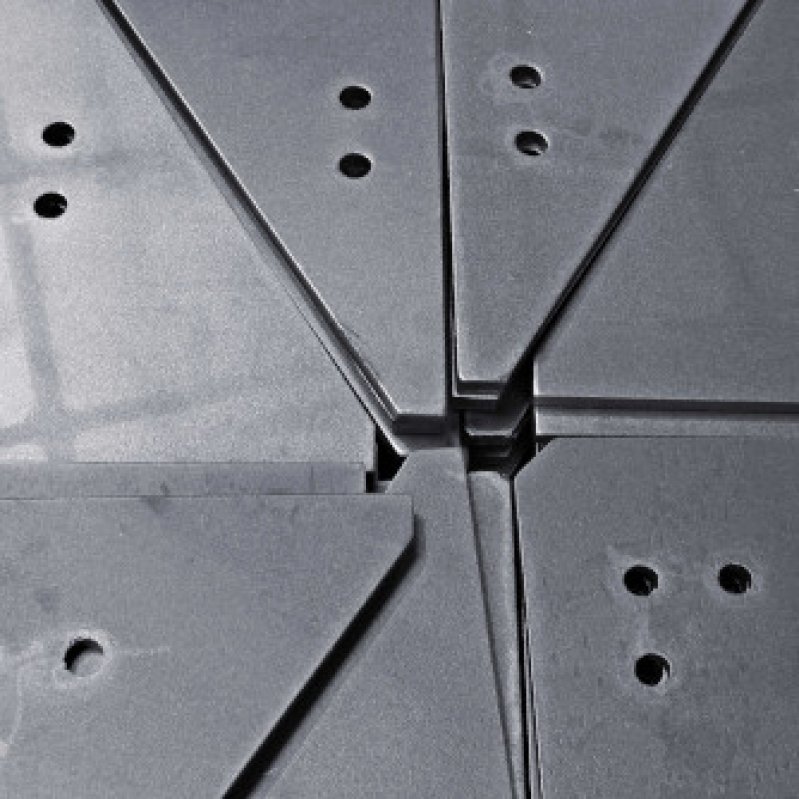

An important element of our activity is the production of steel elements in small, medium and large production series - from several dozen pieces to several thousand pieces. We specialize in the production of elements whose manufacture consists of the processes of laser cutting, bending, welding and corrosion protection. Our own hot-dip galvanizing plant or painting shop are the assets that allow us to offer a comprehensive service with full supervision of each stage of the production process. Many years of experience in manufacturing steel components allows us to optimize the production processes in order to offer competitive prices while maintaining appropriate standards.

Contact

About the product

The manufacturing process, in addition to the fabrication itself, also includes the implementation of production with the design and manufacture of the tooling necessary for welding. As part of the production we also offer assembly, packaging and delivery of the finished product to the customer.

Our welding and quality processes are supervised by an IWE-certified Welding Engineer, who is responsible for supervising product and process quality. Along with the products we provide our customers with: material certificates, measurement sheets, technology sheets.

Production range

Contact our specialist

Do you have any questions for us? Our specialist will be happy to answer them.

CNC processing - laser cutting

Tomasz Juszczyk

Production Manager