About the product

Modern solutions for railways

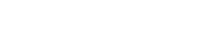

At MABO we strive to make our solutions not only structurally sound but also innovative and modern. That is why our research team in cooperation with specialists from the Faculty of Non-ferrous Metals at the AGH University of Science and Technology has developed a weightless spring tensioner for railway and tram traction with the tension force ranging from 4 to 42 kN. Our device is intended for anchoring the overhead contact line and its operation is based on the weightless forcing of the tensioning force, by using a special system of springs in combination with a system of transmission and regulation of the tensioning force.

Our tensioners are characterized by a simple design ensuring compensation of considerable elongations of contact wires and catenary ropes of the overhead network, and at the same time lower production cost in comparison to the solutions of foreign manufacturers, which are well known and applied. The main difference from older generation devices is the use, instead of gravity weight, of a highly efficient spring mechanism equipped with a cam. The spring mechanism is much lighter than the previously used solutions, in addition, it allows the use of lighter anchor columns and is also cheaper to manufacture.

Contact

Key information

Tensioner benefits

01Easy to install

01Easy to install

02Reduced network inertia during operation

02Reduced network inertia during operation

03No periodic maintenance required

03No periodic maintenance required

04Suitable for installation on all types of catenary poles

04Suitable for installation on all types of catenary poles

05Protected against corrosion

05Protected against corrosion

06Solutions not available for criminal activities

06Solutions not available for criminal activities

07No deposit on packaging

07No deposit on packaging

About the product

Reliable overhead line tensioning system

The main principle of operation of a spring-loading device is to convert the torque of the device shaft, generated by a system of springs, into a force acting on the catenary. The change of the force (torque) characteristics generated by the spring on the shaft during its rotation is performed by a specially selected cam, in such a way as to obtain a constant force as a function of the compensated rope length change. The device ensures a constant level of the required tension force depending on the type of the network, at the same time ensuring compensation of changes in the length of contact wires and suspension cables as a result of temperature changes (change of seasons).

Simple easy-to-install design

There are spring tensioning device solutions on the market, the design of which is based on spiral springs. In that case, an increase in the tensioning force generated by a given device is associated with an increase in the size of the spring or the number of springs required for use, and thus also the weight of the device. Increasing the weight and size of the device leads to difficulties with its installation on traction poles. The design of our solution is based on the use of helical-coil springs with a rectangular cross-section. The use of this type of spring makes it possible to obtain a greater tensioning force and improves elasticity, which in turn improves the characteristics when extending the tension member within the range of constancy of maintained force. At the same time, the geometry of the spring reduces the size of the device as well as its weight and therefore the assembly takes place with a single spanner.

Patented and favourably opined by the Railway Institute

This solution received patent protection in the Polish Patent Office (No. PL228589 B1 - Device for compensating changes in the catenary line length). After favourable results of both laboratory and field tests, the spring tensioning device received a favourable opinion from the Railway Institute confirming that it meets the requirements and can be used in all types of overhead networks. It also obtained the PKP PLK S.A. approval to use our solutions on the railway lines managed by them.

Product specifications

TUN – 1 (Single spring)

Single-spring overhead line tensioning device with tensioning force from 4 to 20 kN. It is used for the upper catenary in railway and tram transport.

Enlarge 3D view

| Index | Siła naci. [N] | Długość kompensacji [mm] | Ilość sprężyn |

|---|---|---|---|

| TUN - 04 | 4000 | 800 | 1 |

| TUN - 06 | 6000 | 800 | 1 |

| TUN - 08 | 8000 | 800 | 1 |

| TUN - 10 | 9530 | 800 | 1 |

| 9560 | 800 | 1 | |

| TUN - 12 | 11670 | 800 | 1 |

| 12160 | 800 | 1 | |

| 12670 | 800 | 1 | |

| 12740 | 800 | 1 | |

| TUN - 14 | 13480 | 800 | 1 |

| 13790 | 800 | 1 | |

| 14000 | 800 | 1 | |

| 14050 | 800 | 1 | |

| 14280 | 800 | 1 | |

| TUN - 16 | 15760 | 800 | 1 |

| 15890 | 800 | 1 | |

| TUN - 18 | 18000 | 800 | 1 |

| TUN - 20 | 19070 | 800 | 1 |

| 19180 | 800 | 1 | |

| 19600 | 800 | 1 |

TUN – 2 (Two springs)

Two-spring overhead line tensioning device with tensioning force from 22 to 42 kN. It is used for the upper catenary in railway and tram transport.

Enlarge 3D view

| Index | Siła naciągu [N] | Długość kompensacji [mm] | Ilość sprężyn |

|---|---|---|---|

| TUN - 22 | 21000 | 800 | 2 |

| 21180 | 800 | 2 | |

| 21230 | 800 | 2 | |

| TUN - 24 | 24000 | 800 | 2 |

| TUN - 26 | 25410 | 800 | 2 |

| 26480 | 800 | 2 | |

| TUN - 28 | 27530 | 800 | 2 |

| 28600 | 800 | 2 | |

| TUN - 30 | 29670 | 800 | 2 |

| TUN - 32 | 31760 | 800 | 2 |

| TUN - 34 | 33880 | 800 | 2 |

| 34940 | 800 | 2 | |

| TUN - 36 | 35000 | 800 | 2 |

| TUN - 38 | 38000 | 800 | 2 |

| TUN - 40 | 40000 | 800 | 2 |

| TUN - 42 | 42000 | 800 | 2 |

Implementation map

Select type

My current location

Location determined automatically by the browser

Address

(street, city)

Contact our specialist

Do you have any questions for us? Our specialist will be happy to answer them.

Director of the Traction Equipment Department

Jędrzej Iskrzycki

OFFERING – TRACTION DEVICES AND EQUIPMENT