About galvanizing

Long-lasting and reliable protection against corrosion? It's possible!

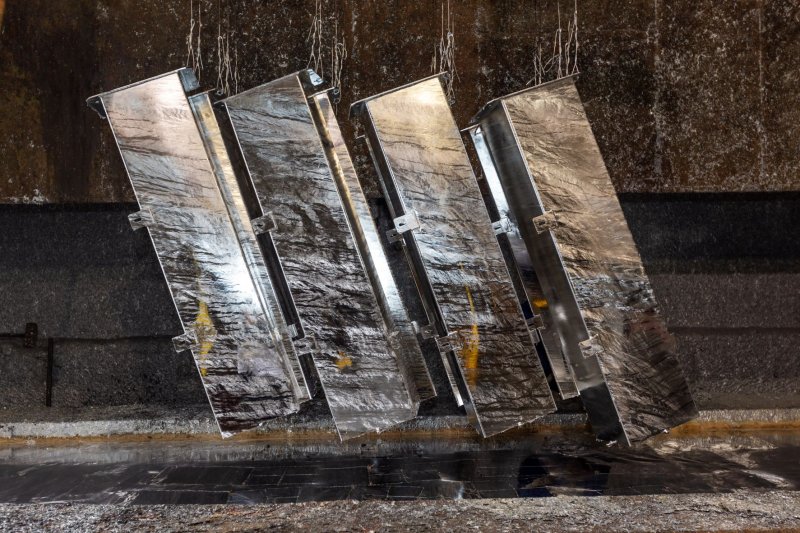

Hot-dip galvanizing gives valuable, long-term and robust protection against corrosion. It is the least expensive, most effective and most popular way of anticorrosion protection, while not changing the steel properties.

The application of zinc coating on steel consists in immersion of previously prepared steel components in a bath of liquid zinc at a temperature of about 450 °C. We are a member of the Polish Galvanizing Association. We galvanize in accordance with the EN ISO 1461 standard.

Contact

Key information

Advantages of the hot dip galvanizing process:

01Precise covering of parts, even in hard-to-reach confined spaces (e.g. inside pipes)

01Precise covering of parts, even in hard-to-reach confined spaces (e.g. inside pipes)

02Thorough cleaning of the surface of the galvanized material using chemical processes

02Thorough cleaning of the surface of the galvanized material using chemical processes

03Zinc layer life from 20 to 65 years, depending on weather conditions

03Zinc layer life from 20 to 65 years, depending on weather conditions

O PRODUKCIE

Hot dip galvanizing - what does the process look like?

An iron-zinc alloy coating is formed during the immersion of the component, which is the result of a relatively complicated process of mutual diffusion of the atoms of both metals during the formation of the basic intermetallic bonds and subsequent phase transitions.

Formed by the iron-zinc alloy, the coating is durable and resistant to environmental and mechanical damage. Even after damage to the coating, the iron-zinc alloy, protects the product from corrosion, which is why galvanizing steel is so effective.

In what weather conditions can the the galvanized elements be used?

Being inert to the environment, the zinc coatings can be used in all conditions. They perform well in well-ventilated rooms, but also outdoors. They can be used without any problem on components in contact with water, the temperature of which does not exceed 60 °C. Hot-dip galvanizing is not suitable for components operating in acidic and strongly alkaline conditions.

Hot dip galvanizing furnace dimensions:

Our furnace allows galvanizing of elements with maximum dimensions of 6,2 m x 1,3m x 2,2m and weight not exceeding 2 000 kg.

We invite you to do business with us and to get acquainted with the general conditions of hot dip galvanizing in MABO Sp. z o.o: General Conditions of Hot Dip Galvanizing Services at MABO Sp. z o.o.

Examples of projects